An aircraft Engine must be carefully monitored. It should also have certain controls in place to control the engine in a situation where they pilot must step away or is incapacitated. Unlike the sensors that you find in your car, they do not just let you know when the engine is not getting enough oxygen.

An aircraft Engine must be carefully monitored. It should also have certain controls in place to control the engine in a situation where they pilot must step away or is incapacitated. Unlike the sensors that you find in your car, they do not just let you know when the engine is not getting enough oxygen.

These sensors are the central nervous system of vehicles that launch in any way. They also help control the support system of the plane. These sensors provide instant feedback to the computers in the plane and controllers.

These sensors and accessories do not work alone. Through real-time monitoring and reconfiguration, air-traffic control is able to monitor the control and health of the vehicle. Most of this information is obtained while the plane is still on the tarmac. It allows controllers and maintenance workers to ensure that the plane is ready and safe for flight. It also provides information about various propulsion systems during testing. After takeoff, it provides the pilot with information about how the plane is functioning at various intervals of time.

Propulsion System

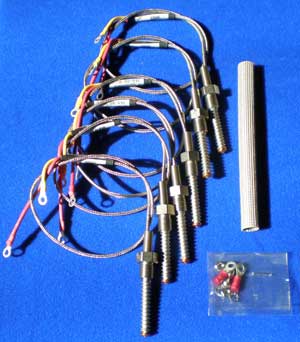

Propulsion systems are any system that provides the thrust necessary to launch the vehicle off of the ground. The sensors inside these are used to monitor the parameters associated with the the vehicle, such as the launch, lie the load, engine temperature, pressure in the engine, and the amount of vibration the engine is experiencing.

What are Avionics

Avionics are the components in the Aircraft Flow Sensors. They are also used in rockets and satellites. They carry out important functions including navigating the plane and communication controls. They collect and interpret important information from the systems and store them for later use by computers to determine the success of the flight and any repairs that need to be completed after the plane lands. These components are tested well in a laboratory setting to ensure that they function properly in all situations.

Manufacturing and Testing

Manufacturing and testing these devices for durability and functionality are extremely important. If one of these malfunctions, they can cause serious problems when in flight. Because of this, the manufacturing process is completed very carefully and they are tested in extremely strenuous environments to ensure that they do not have any defects.

Learning how the different aircraft components are made shows us a lot about the effort put into their creation. Their components are tested more rigorously than any other vehicle parts on the market today. This is why they say flying in a plane is safer than driving in a car. Aircraft Engine Monitors are considered safer since car components only go through the rigorous tests like the ones described above when there is a failure of equipment over a large number of vehicles.